![]()

![]()

![]()

![]()

Arched Through Truss Bridge - LegoWorld 2005 Bridge strength contest

A bridge strength contest was organized by FreeLUG and De Bouwsteen during LegoWorld 2005. The purpose of the contest was to build a bridge crossing a 100 studs / 80 cm gap, and load it at its center. Detailed rules are here: English / French.

The contest

There were 5 bridges enrolled in this contest, here is the roster.

Gerrit Bronsveld and Martijn Boogaarts brought a HUGE and massive beam whose core is made from layered plates on side. This monster far exceeded the mechanical limits of the tester unit (about 100 kg - 220 lbs) and won the contest easily. It also showed a loophole in contest rules that should have limited the weight of the bridge. |

|

Marc Schickelé's bridge was also a beam composed of side placed bricks and won the second place, exceeding too the tester limits. But the sag showed that we were close of the maximum load. |

|

My own arched bridge performed quite well with a 76 kg (167 lbs) load when it burst into pieces. |

|

Menno Gorter built a nice white arched bridge. Unfortunately the attach point failed at 44 kg (97 lbs) |

|

Jean-Louis Bergamo had a very cute bridge with string-suspended deck. It broke at 40 kg (88 lbs). |

|

|

|

Preparation of the contest

The bridge contest was originally proposed by Richard "Vauban" Olivero for Freelug meeting in July 2006 (see photos here). For the load we used a bucket progressively filled with water. This testing method was clearly not sufficient for the most sturdy bridge, so Richard and I built a tester for LW2005.

Richard attaches the measuring device (a 30 kg rated dial balance) to the frame. |

|

A hoist that can be configured as 2x or 4x allows two measuring ranges: 0-60kg and 0-120kg. Unfortunately, a somewhat lousy mechanical construction limited the effective maximum load to 100 kg (220 lbs). |

|

A screw driven by a crank pulls a chain through a nut. The chain itself pulls the hoist strap. A second chain with a hook allows to release the main screw drive, reset it, attach it further and pull again. This lengthy process was a bit clumsy, but it worked... |

My entry

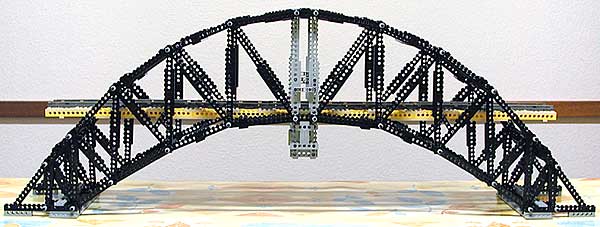

The bridge I built for FreeLUG contest was almost a joke (though it was tough), and certainly very ugly. For LegoWorld, I decided to build a nice arched bridge... |

|

Here is the result. Notice the two diagonal girders on top of the bridge, used to keep it straight. The beams were fixed to the bridge with hinge plates on top and bottom - a rather weak connection. I suspect that one of the hinges popped out under load and caused the explosive failure of the bridge. |

|

Special thanks to TJ Avery, his bridge calculation spreadsheets (and his tips on huge constructions) helped me a lot. Here is the spreadsheet with the values I used for this construction. As my bridge was rather short, I used fewer sections than TJ's design, so the first 3 sections are collapsed into a single vertical beam. |

|

Some members are doubled to provide more symmetrical efforts on axles when the bridge is loaded. |

|

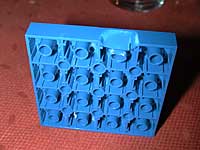

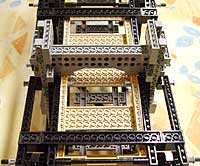

Inside the bridge. The deck has no mechanical job, but contest rules called for tracks and opening large enough for a train. |

|

Bottom view. |

|

Attach point for the load. It was further reinforced before the competition but looked quite warped before bridge failure. |

|

I also added a string between bridge ends to prevent their separation. It is made from liftarms assembled with old 1x6 Technic plates. |

![]()

![]()

![]()

![]()