![]()

![]()

![]()

![]()

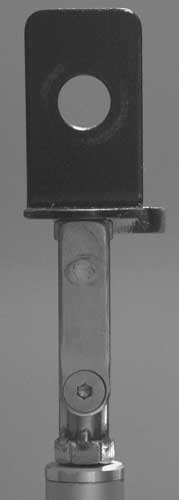

The rotator consists of 2 parts.

The L-shaped one has 2 holes. I modified one tripod screw to attach the camera so that it has a short stud at the end. Reason: The thread goes deeper into the camera, and the friction diameter increases. The lower part of the L has the other hole. I welded through it to attach the screw without damaging the head. I added a little stop (the hook which I welded against the vertical part of the "L"). This is to precisely define the roll angle of the camera.

The other part is a piece of tube 12x2 which can take the shaft of the screw exactly (I cut off the threaded part of the screw). Then I welded a M8 nut under the tube.

As I had not the right tool to cut these photo threads (and I didn't want to buy one) I used an old adapter screw for my middle format equipment (male side: bigger thread, female side: standard) and replaced the bigger one with M8. This works fine.

The leaf spring is attached with an M5 screw. I found out that it may be pushed sidewards if I move the camera, so I added a little pin (2.5 mm diameter). This pin goes through the upper end of the spring (weld spot on the outside) and goes through a corresponding hole in the tube wall.

I painted the upper side black to avoid reflections (I'm always using stainless steel or aluminium - I hate to deal with corrosion).

All 3 angles are reproducible: Yaw due to the 6 sided shape of the screw head (I always take the 1st pic so, that the leaf springs is showing to the rear side of the scenerie, and rotate then clockwise to keep the M8 thread tightened. Just in case if the head of the screw isn't regular enough). Pitch due to the bending angle of the "L", and roll due to the hook.

|

|

|

|

|

Photos & description ©

Stefan Wode 2001

![]()

![]()

![]()

![]()