![]()

![]()

![]()

![]()

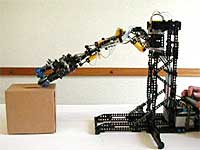

Pneumatic

Arm

I wanted to try a big pneumatic construction

(my pneumatic parts collection is at last large enough) I settled

on an arm, loosely modelled after the human one. Here is a detailed

description...

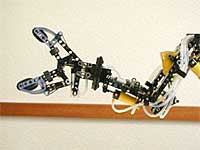

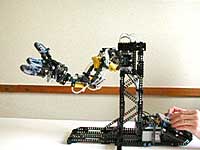

The arm

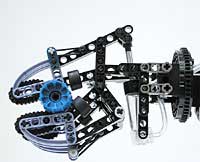

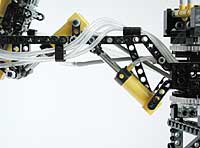

The hand has three fingers, a single piston is used to open and close it. |

|

The shape of the hand adapts itself to the object grabbed. Chrismaker told me about this page that describes the trick, he also used it in his outstanding robotic hand |

|

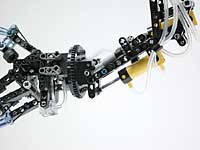

The wrist can flex... |

|

...and rotate too. Piston linear motion is converted to a rotation one by a lever, gears and a universal joint transmit motion to the wrist turntable. |

|

Wrist and hand viewed from top and bottom. |

|

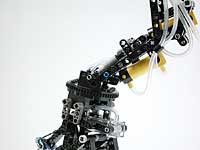

The elbow has a lever mechanism to increase flex angle. But there is a cost: two parallelled pneumatic cylinders have a hard job lifting the hand. This is also the reason why this arm remained skeletal: I originally intended to add a skin, but the weight would have been too much to be properly moved. |

|

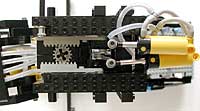

Two parallelled pistons raise the shoulder. |

|

Rotation of the shoulder. |

|

Details of the mechanism used to rotate the shoulder. |

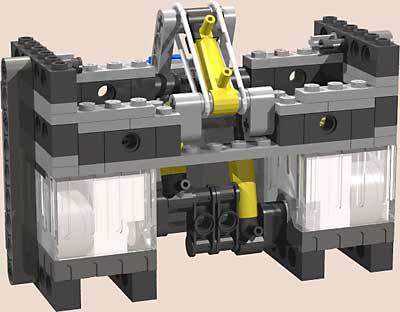

The control unit

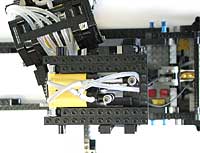

The control unit contains a battery pack, the compressor and the command switches. I had to carefully select the switches I used: some of them were leaky and did not allow the pressure to build up enough to move the elbow or the shoulder joints. |

|

The compressor is based on two small pumps, working in opposition. They are driven by two clear "monkey" motors that are faster and slightly more powerful than regular ones. A small piston, loaded by two rubber belts, moves an electric switch when pressure is too high. The compressor motors are then switched off. |

|

The opened console shows some gory details... |

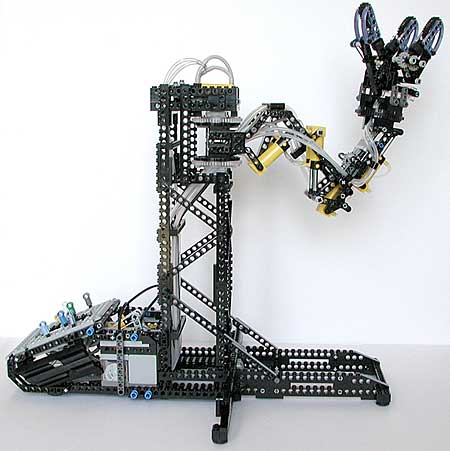

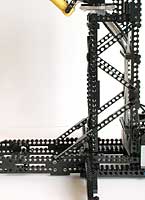

The stand

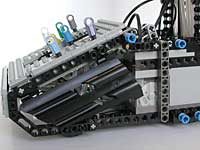

I first tried to build the support tower using only studless beams, but the result was not stiff enough. So I rebuilt it using the more traditional beams-and-plates method. |

|

Balancing the arm requires a pretty big foot! |

LDraw files

I have modelled the arm and the compressor.

Movies

The pneumatic arm in action (AVI movies, Divx 5.1 compression)

Hand and wrist movements (400kb). |

|

Exercising the arm (900kb). |

|

Moving an object (800kb). |

![]()

![]()

![]()

![]()