![]()

![]()

![]()

![]()

- Stable 9V output up to full discharge

- Easily handles 5A power demand

- The included batteries are 2040mAh 18500 cells with a total capacity of 14.6Wh

- USB-C charging port for 2A fast charge

- Built-in battery protection for overcharge, over-discharge and overcurrent

- JEITA temperature profile compliant charging

- the built-in electronics has powerpath management capability, which means that if you are not satisfied with the capacity of the battery, you can increase it by connecting any powerbank to the USB-C port. This also means that the HUB is capable of continuous operation from the charging cable.

- Variable voltage output (two LiPo cells voltage, between 6.5V and 8.4V

- Lower capacity (850mAH)

- You can't charge it while using it.

- Starting arm rise at half power (motors PWM duty cycle of 50%). This was done to avoid too strong mechanical test: I didn't want my tester to break in the middle of a test!

- Full power is applied. Current increase to its maximum for a short time, as the motor has to overcome gravity and weight inertia). When the high point is reached, the motors are left coasting, inertia completes the movement (again, the purpose is to avoid too strong forces on the tester). Note that I didn't use regulated move mode to make sure to apply maximum power to the motors.

- Motors are coasting, during this phase the motor drivers are disabled in low power state. Overall hub consumption is minimal, about 80mA.

- Motors are returned to 0 position (straight down). This time regulated mode is used. Current is much lower as only inertia must be overcome, gravity does the rest.

- After 0 position is reached, motors are maintained in position in brake mode. While no current flow in the motors, the motor driver chip are still active and draw some current: overall current is about 180mA, more than twice the current in phase 3.

Batteries

for Powered Up Technic/Control+ hub: a "real life"

endurance test

I recenly received a prototype of Phondly EnBo PU Battery Pack for the Technic hub. So I had to do again some battery technology comparison... Instead of an "abstract" test like I did in my previous battery test, I made a "real life" one, using a Technic contraption lifting weights.

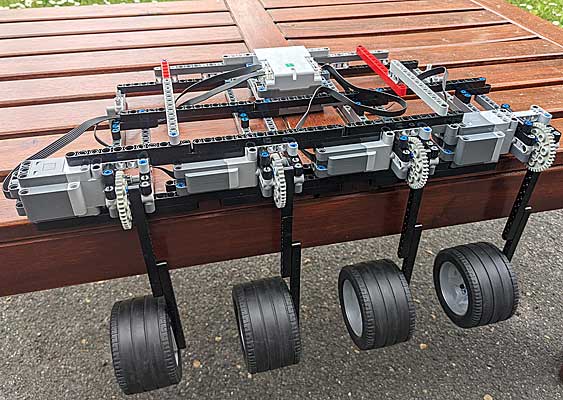

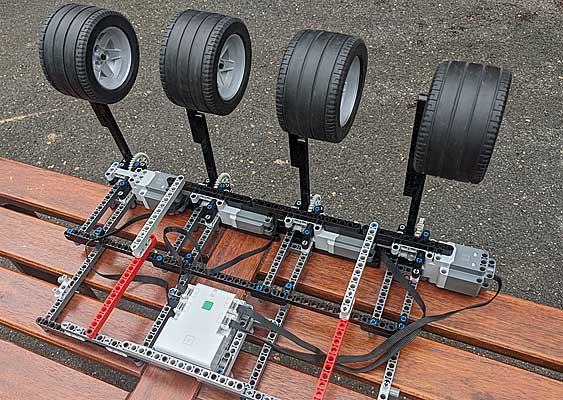

4 motors (2 x Powered Up L, 2 x Powered Up XL) raise arms with a large wheel and heavy tire (through a 1:5 gear reduction). Since the thing is rather noisy and runs for hours, I installed it outdoor... The slits of my garden table also allows to anchor the tester, preventing falls.

The tester is programmed with a Pybricks

Python script. Pybricks allows to create log files, and to access

internal current and voltage sensors of Technic hub. This was

thus the language of choice for this kind of experiments! The

program is available here.

Thanks to Laurens for the help provided to create log files

with Pybricks!

Building instructions

Battery rooster

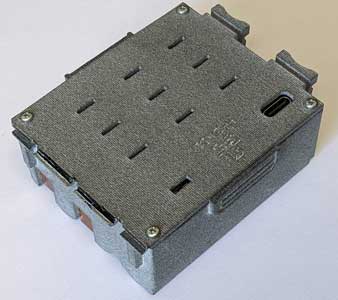

Phondly EnBo PU Battery This is the thing that motivated this test. Still at prototype stage, it should be the subject of a KickStarter campaign in May 2022 to improve its availability. More details here. Technical specifications |

|

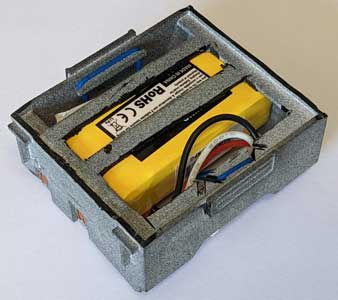

My own LiPo battery This is the "build your own" LiPo battery that I described here. Compared to Phondly solution, it shows several drawbacks: On the positive side, it is very simple, easy to assemble without too much special equipment, and its components are pretty cheap. |

|

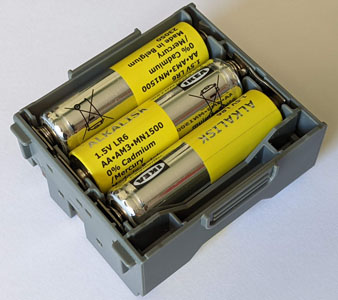

Alkaline cells The simplest solution... alkaline, non-rechargeable cells. I tested with the cheap Ikea "Alkalisk" cells. Some branded batteries do have somewhat higher capacity, but my own tests tend to prove that this capacity increase is not worth the premium cost. Inherent to the technology, these batteries have

the highest voltage variation during discharge,

from more than 9V for fresh ones down to 5.4V fully

depleted. Your motors speed will change accordingly

;) A more subtle parameter is battery impedance. A higher impedance means that there will be a greater voltage drop when high current is required. We'll see the impact of that parameter when comparing motor performance with alkaline and NiMH cells. Note that this parameter might be better with branded cells! |

|

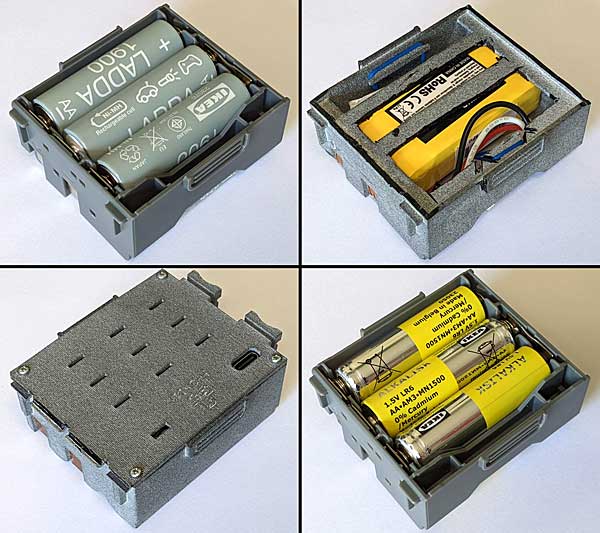

NiMH cells I also tested NiMH cells, more specifically Ikea "LADDA" low capacity version (1900mAH). This one is at the same time cheaper and more rugged than the high capacity version (2450mAH). All I can say is that they work pretty well... Output voltage is variable (between 6V and 8.4V) but output impedance seems pretty low. |

Testing the tester!

The first test I performed was to record voltage and current in a close loop to see the level of stress applied by my contraption to the battery and hub.

While lifting the arms, the current reach 2 Amperes, close to the maximum that the hub can provide (LB1836 is specified up to 520 mA per channel). Unfortunately, the measured voltage has a problem: it INCREASES as the current increases. Since the battery I used (my LiPo one) is purely passive, this must be an artifact caused by crosstalk between voltage and current measurements! In the following measurements I measured current only while the motor are off, and current is minimum. This also prevented me from doing direct measurement of battery impedance...

Zooming on one cycle... It can be broken in 5 phases:

Capacity

A rough evaluation of battery capacity is given by the number of cycles a full charge can perform.

As expected my 850mAH battery is the worse performer, EnBo and alkalines are roughly on par, NiMH has the most stamina.

Voltage and variation

This chart shows battery voltage as it is progressively discharged. The voltage is measured during the idle time of the motors to avoid the crosstalk problem mentionned above.

We can see that EnBo battery provides a rock steady 9V voltage (actually a bit more but I suspect that the value returned by the hub is a bit high, an external voltmeter measures precisely 9V). When it is exhausted the battery shuts down without any warning. This should be improved in production version, providing a voltage drop slightly before failure.

A more synthetic view, using average voltage and standard variation charts:

EnBo solution is obviously the winner here, with the highest and most stable voltage. Alkaline cells fare the worse, with the lowest average voltage! Its nominal 1.5V per cell rapidly decreases, and this chemistry has the highest voltage change during discharge. NiMH has a lower nominal voltage, but its voltage change is much lower.

Performance

I evaluated battery performance from the time needed to rise exerciser arm. This is of course correlated to battery voltage, the motors provide more power with a higher supply voltage and raise the weight more rapidly.

Interestingly, voltage of alkaline cells appear higher than NiMH or LiPo, but rising speed is actually LOWER except at the beginning. I suppose that the higher internal impedance of alkaline cells limits performance!

A more synthetic view, using average voltage and standard variation charts:

With its regulated constant output voltage, EnBo battery is the clear winner, with faster rise time and no speed variation as the battery drains.

Weight

The last parameter is the weight... The complete hub can weight from 110g with my LiPo battery up to 220g with NiMH cells. Note that weight is an ambivalent parameter: lighter weight is a good thing for vehicles that will have a better acceleration, but a drawback when used as a counterweight in cranes or manipulator weight!!!

![]()

![]()

![]()

![]()